Source factory & No middleman !

Cleanroom wipes manufacturers since 2004

- Provide specializing in OEM & ODM One- Stop solutions

- Competitive pricing for all cleanroom products

- Reliable service and fast response support

- Accept small brath samples order

With more than 20 years of experience in cleanroom consumables, Kingclean is equipped with advanced production facilities.

Kingclean has precision lines, expert R&D, and ISO quality ensure reliable, customizable cleanroom supplies.

24/7 excellent service team will be with you throughout the entire process, from production to after-sales.

Our Product

Our options include polyester, microfiber, submicro denier and anti-static materials, all offering high absorption, low lint, and full customization to meet specific customer needs.

Polyester Wipes

Durable polyester wipes for general cleanroom use.

- Model: KC 1009D/ LE

- Size: 4*4/ 6*6/ 9*9 Inch

- Basis weight: 150 g/㎡

- Absorbency: 387 ml/ ㎡

- Thickness: 0.55 mm

Submicro Denier Wipes

Blended fibers offering improved surface contact.

- Model: KC 4008

- Size: 4*4/ 6*6/ 9*9 Inch

- Basis weight: 100 g/㎡

- Absorbency: 319 ml/ ㎡

- Thickness: 0.30 mm

Microfiber Wipes

Fine fibers designed for higher particle removal.

- Model: KC 1809

- Size: 4*4/ 6*6/ 9*9 Inch

- Basis weight: 160 g/㎡

- Absorbency: 431 ml/ ㎡

- Thickness: 0.42 mm

ESD Wipes

Wipes with antistatic properties for ESD areas.

- Model: KC 3008

- Size: 4*4/ 6*6/ 9*9 Inch

- Basis weight: 150 g/㎡

- Absorbency: 387 ml/ ㎡

- Thickness: 0.55 mm

Wipes Roll

Continuous roll wipes for extended, routine use.

- Material:100% polyester fiber

- Size: width:7mm-1.65m; length:10M-500M

- Basis weight: 112 g/㎡

- Absorbency: 302 ml/ ㎡

- Thickness: 0.32 mm

Nonwoven Wipes

Wipes with antistatic properties for ESD areas.

- Model: KC 609

- Size: 4*4/ 6*6/ 9*9 Inch

- Basis weight: 68 g/㎡

- Absorbency: 245 ml/ ㎡

- Thickness: 0.28 mm

Dust free wipes

Continuous roll wipes for extended, routine use.

- Model: KC M-3

- Size: width:7mm-1.65m; length:10M-500M

- Basis weight: 35 g/㎡

- Absorbency: 236 ml/ ㎡

- Thickness: 0.22 mm

Clean Paper

Continuous roll wipes for extended, routine use.

- Material 55% woodpulp + 45% polyester

- Size: 11*19 CM

- Material: 100% raw wood pul

- Packing: 280 Pcs/Bag, 60 Bags/CTN

SMT Stencil Roll

Continuous roll wipes for extended, routine use.

- Material 55% woodpulp + 45% polyester

- Size:300 CMx10 M

- Basis weight: 56g/㎡

- Absorbency: 5.2 g/g

- Thickness: 0.3 mm

Wiper Paper Roll

Continuous roll wipes for extended, routine use.

- Color: Bule/ White

- Basis weight: 68 g/㎡

- Size: 25*38 CM

- Material 55% woodpulp + 45% polyester

- Packing: 500 Sheets/Roll, 4 Rolls/CTNR

Cutting Types

We offer thermal, laser, and ultrasonic sealed edge options to ensure precise sizing, low particle release, and reliable performance for different cleanroom requirements.

Thermal Sealed Edge

- Heated blades melt fibers to form a sealed edge.

- Cost effective sealed edges with reduced fraying.

- Heat may cause edge stiffness or slight deformation.

- For general cleanrooms with moderate cleanliness needs.

Laser Sealed Edge

- Laser melts and seals the edge with precise control.

- Clean, low lint edges with high dimensional accuracy.

- Edge may slightly harden or show minor discoloration.

- For high grade cleanrooms needing sealed, low particle edges.

Ultrasonic Sealed Edge

- Ultrasonic vibration bonds fibers for a smooth sealed edge.

- Soft, smooth, lint free edges without heat damage.

- Less effective on very thick or dense fabrics.

- For high purity environments requiring soft, clean edges.

Six Core Advantages

Designed to deliver a better user experience, our cleanroom materials offer stable, reliable, and efficient performance across diverse applications.

Soft Touch with Eco Benefits

Gentle, safe, and environmentally conscious.

Excellent Absorption & Oil Removal

Fast absorption for clean, residue free wiping.

Suitable for Multiple Environments

Ideal for labs, cleanrooms, optics, electronics.

Strong Chemical Resistance

Stable against common solvents and chemicals.

Low Ion Content

Minimized ions for sensitive cleanroom use.

Lint-Free & Dust-Free

Designed to reduce particles and contamination.

Fully Customizable

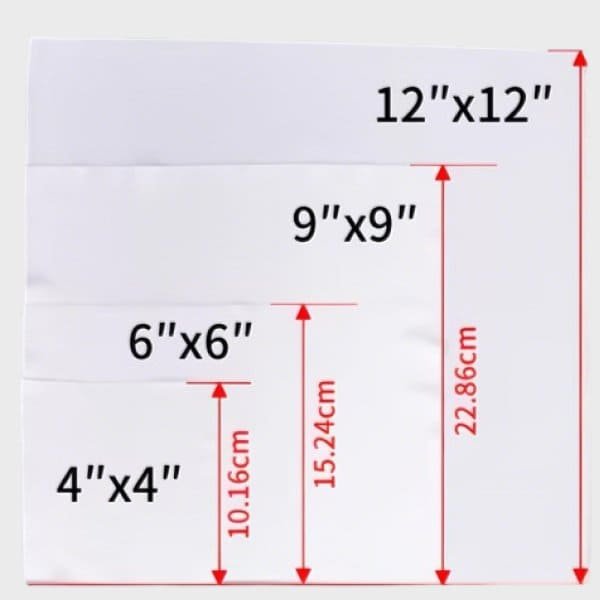

Custom Cleanroom Wipes Your Projects

- Material: Polyester fiber, microfiber, submicro denier

- Size: 4×4/ 6×6/ 9×9/ 12×12inch or customized

- Weight: 150g/㎡ ±3g, or customized

- Cutting Method: Ultrasonic or laser

- Packaging: 100 pcs/bag, 20 bags/carton, up to you

- Absorbency:319 mL/㎡

How to Manufacture Cleanroom Wipes

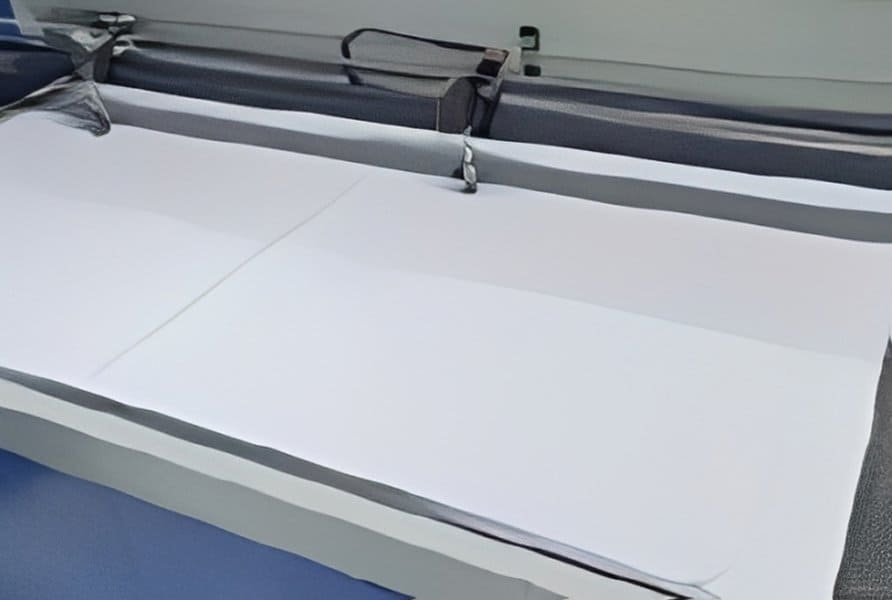

Cutting & Sealed Edges

Edges are formed through laser, thermal, or ultrasonic cutting to reduce loose fibers and keep consistent dimensions for later processing.

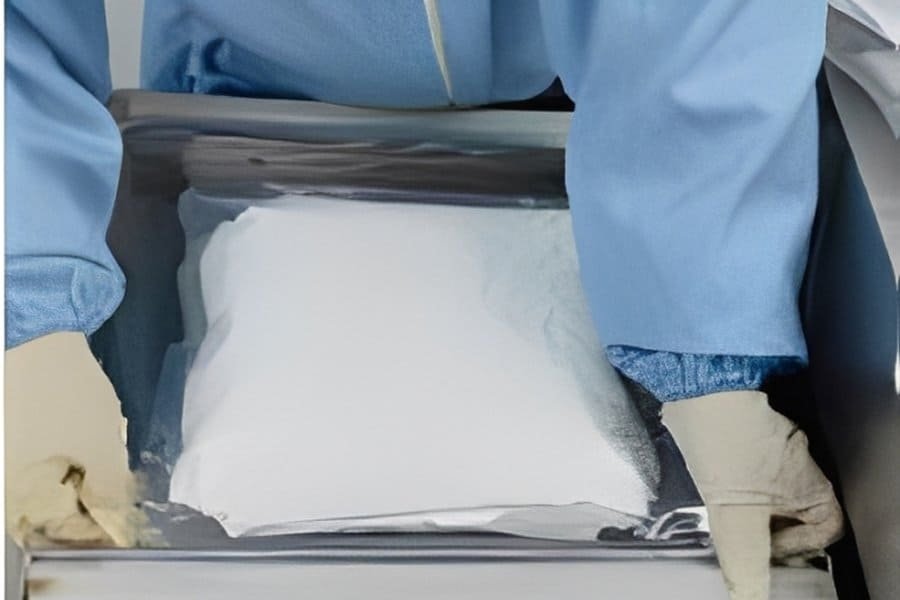

Cleanroom Washing

Materials are washed in controlled rooms to remove surface particles and residues, helping stabilize cleanliness before drying and packaging.

Sorting & Folding

Wipes are checked to remove defects, then folded and packed following set specifications to maintain consistency in size and appearance.

Drying

Washed materials are dried in filtered cleanroom conditions to limit airborne particles and prepare the wipes for sealing and packaging.

Vacuum Packaging

Products are vacuum-packed to reduce air exposure and particle introduction during storage and transport, following standardized procedures.

Quality Inspection

Batches are inspected for size, appearance, and cleanliness, and results are recorded to support traceability and production control.

Our services

From industrial production to electronics manufacturing and cleanroom operations, we provide reliable quality and performance for every need.

Semiconductors Clean

Removes particles for clean chip processing

Precision Instruments Clean

Low-lint cleaning protects accuracy

Electronics Clean

Cleans components to ensure reliable assembly

Cleanroom Clean

Suitable for controlled, dust-free environments

Laboratories Clean

Ensuring clean, particle-free handling.

LED Displays Clean

Streak-free cleaning keeps screens clear

About Kingclean

Huizhou Kecheng Purification Technology Co., Ltd., based in Huizhou, Guangdong, manufactures cleanroom consumables with advanced production lines inherited and upgraded from Shenzhen Kingclean Technology Co., Ltd. (establish in 2004).

We operate 10 self developed cleanroom wipe production lines, offering customization in material, size, cleanliness, packaging, and cutting methods (laser, ultrasonic, thermal sealed edges). With a daily capacity of 10 tons, we provide stable supply and lead times of 3–15 days.

Our wipes minimize particle shedding, prevent scratches, improve surface cleanliness, enhance solvent absorption, reduce defects, ensure consistent performance, and support strict cleanroom standards.

With exports to 25+ countries, ISO-based quality control, factory direct pricing, flexible MOQs, and reliable global supply, we are a trusted partner for international distributors and B2B buyers.

Professional, enthusiastic and reliable cleanroom wipes specialists

Whether you need custom consumables or technical guidance, let our experienced team help you achieve precision, cleanliness, and efficiency in all your cleanroom projects.

Project Construction

With proven experience and reliable manufacturing, we present our cleanroom products and engage with customers to explore practical solutions and applications.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Yes. We are dedicated to designing and providing high-quality cleanroom purification solutions. Our factory operates in full compliance with the ISO 9000 Quality Management System.

Absolutely! You can choose the size, packaging, and even the material. We ensure everything is perfectly tailored to your project needs.

All products of our company will be produced with reference to international standards.national standards, and industry standards. lf there are no products standards, we will formulate the industry standards.

Normally around 3–15 days, depending on the order quantity and specifications.

We ship by sea, air, or express (UPS, DHL, FedEx, TNT, etc.).

Get Samples Now !

Premium cleanroom wipers, purification supplies, and fully customized solutions, each designed to meet strict contamination-control standards. Contact us for samples and let’s begin our partnership.

Want to find the source factory to save money in the middle?

With a source factory where cleanroom wipers can be customized in material, size, packaging, and backed by years of manufacturing expertise, choosing us ensures maximum value, consistent quality, and reliable support for your purification needs.